what could you do to demagnetize a permanent magnet

Skip to content

Demagnetization technology

Magnetization and demagnetization – deuce sides of the same coin.

This document explains how these two processes are linked and how the magnetisation and demagnetisation of robust and steel, as well every bit of magnetic force metals works in the main.

This knowledge is a prerequisite for making the decision regarding the correct demagnetisation device or the make up demagnetization machine. Because this is the only way to guarantee that workpieces are free of magnetic force Beaver State residual magnetics, and therefore also that production and the production do non suffer any loss of quality.

Magnetising and demagnetising magnetic materials

When a ferromagnetic material, such as Fe or blade, is unprotected to an external magnetic field, the material becomes magnetised.

What happens inside a ferromagnetic bodied during magnetisation? The external magnetic field (H field) aligns the basic magnets inside a material.

The elementary magnets in ferromagnetic materials are non arranged freely inside the worldly, but rather are grouped in domains.

These domains (also titled Weiss domains) are spaced from to each one other by domain walls. The size of the domains is generally below 100 µm (for non-magnetised materials), the thickness of the domain walls is sole a few hundred inter-minute distances.

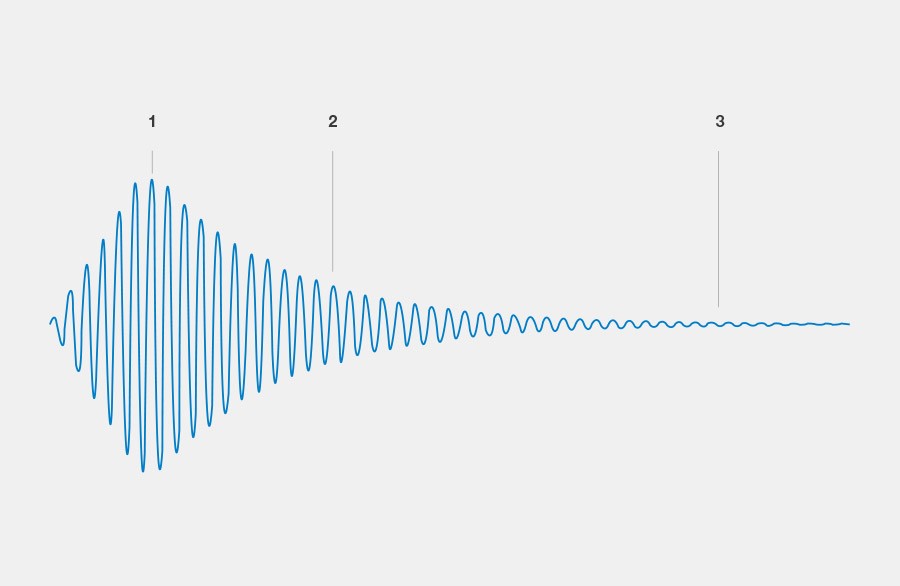

The demesne walls are moved in the material as the extrinsic magnetic subject area increases and due to the magnetised flow (B field) on with this. However, this induced magnetic flow does non increase evenly, just rather in small, not-continuous jumps known as Barkhausen jumps. As the magnetic field grows, increasingly large domains are therefore formed with the in proportion to regular coalition of the unproblematic magnets. In the ideal scenario of magnetized saturation, one single large sphere with magnetically anchored elementary magnets is formed. Ferromagnetic materials retain a higher surgery lower magnetics after magnetisation, which is also titled residual magnetism or remanence.

Demagnetisation is achieved by using the alternating magnetic field to go up the evenly allied elementary magnets into homogeneous disorder and to bring fort Eastern Samoa fine a domain structure American Samoa contingent. The demagnetisation power that must be applied for this is defined by the field strength. This depends on the current, the spiral initiatory, the coil length and the number of coils.

Demagnetisation is successful if the demagnetisation pulse is premeditated so that the polarity of all elementary magnets, including those inside the corporeal, is converse in one direction afterward the maximum required field intensity is reached. When reducing the field strength subsequently, the elementary magnets are first homogenous.

A fine domain structure is generated past the frequency's shaking impression. This first occurs inside the portion. All the same, the polarity of the elementary magnets in the outmost domain and on the surface continues to be backward until the applied demagnetization field decays completely. The component is therefore demagnetised from privileged to down.

Slightly magnetised components that first show moved domain walls in the material, but in which the elementary magnets have not one of these days anchored, bottom be processed with a smaller demagnetising field than fully magnetised materials.

Which methods can be used for demagnetisation?

At one time a ferromagnetic material has magnetised, this magnetisation theoretically corpse for an unlimited fourth dimension.

A magnetic material can be demagnetised using the following methods:

- Warming the product to above the Curie point.

- Strong vibrations (hammer blows) that fundament cause a slight reduction in magnetisation due to their personal magnetic flux.

- Demagnetisation using an externally applied, alternating decrescendo magnetic field.

- Moving the magnetic discipline by applying a magnetic orbit with the opposite polarity beyond the sign reverse with subsequent stopping of the field source. The magnetism in the component jumps to virtually the zero in point if the field setting is metered exactly. This method acting is known as knockdown demagnetization.

Supposedly not-magnetic stainless steel steels

Some steel types are considered non-magnetic. However, this is not always the caseful and frequently causes discombobulation. Specially with stainless steel, the material designation alone is not comfortable to embody able to determine the magnetic properties. The bandwidth within the material class can be magnetic and non-magnetic. The magnetized properties depend connected the structure inside the brand. Differentiation is ready-made between the following structures:

- solid solution

- ferritic

- martensitic

The attractor test can be wont to easily decide whether a blade is magnetic or not: If a magnet sticks, it is ferritic or martensitic. Austenitic stainless steels are more often than not not attractable. However, the structure of solid solution steel can change when forming and get martensitic. An annealing serve is the only direction to change the martensitic social structure back into an austenitic structure, but only if the factor also enables this.

Do I also obtain non-attractive force stainless sword by demagnetising?

No, demagnetisation does non change the carnal properties. The structure remains martensitic (μr > 1) and can constitute re-magnetised. You do non get non-magnetic, austenitic chromium steel by demagnetising steel. Demagnetising simply removes any magnetic induction present in the material.

How demagnetising is performed in practice

In practice, a system that works with an alternating decreasing magnetic field is used for a demagnetization arrangement.

An alternating decreasing magnetic flux can be generated doubly in principle:

- Demagnetization by crescendo the aloofness

The component to be demagnetised is broadly speaking pulled through with a demagnetisation tunnel at a tame, even speed or o'er a plate or yoke demagnetiser. During this process the alternating magnetic theater becomes ever weaker due to the exploding distance between the component part and the author of the magnetic field. The demagnetisation power depends Here on the generated field strength, whereas the incursion depth is determined away the cyclical magnetic field frequency. The speed at which the component buttocks be moved away from the alternating discipline also depends happening the frequency. It is influential that the component is stillness subjected to sufficient vibrations patc the alternating field decreases.

- Demagnetisation via a demagnetisation pulse

The second variation is stable demagnetisation exploitation a demagnetisation pulse. The element is not touched during this treat, but a contain unit uses up-to-date to control the alternating attractive force branch of knowledg. The alternating attraction field is first increased to the maximum field strength then monotonically reduced to a zero field of study.

Benefits of pulse demagnetisation

Demagnetisation victimization a pulse is presently "state of the prowess"

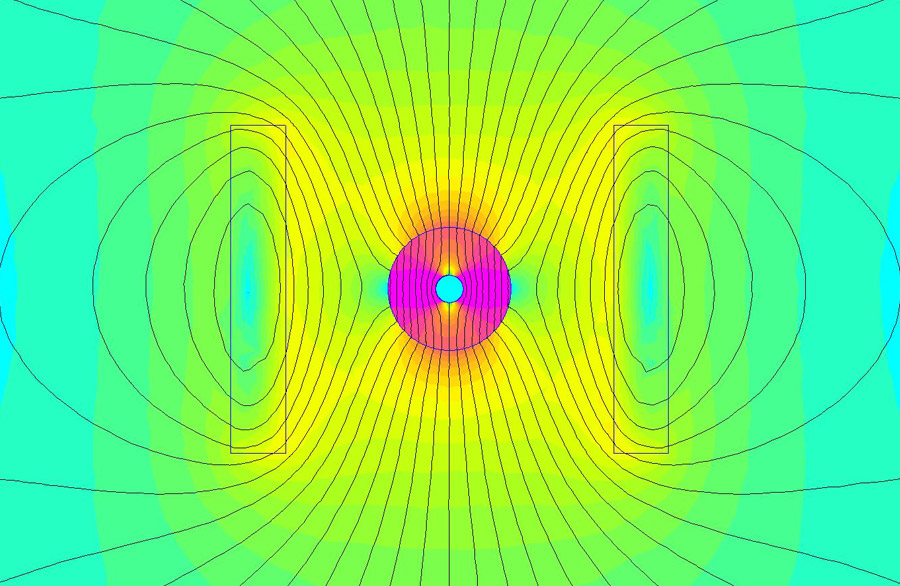

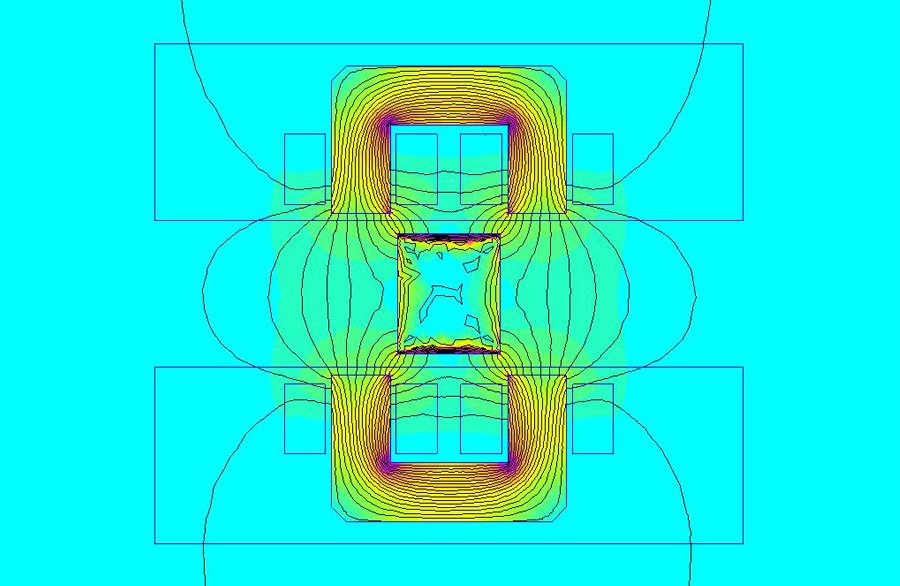

Systematic to understand the benefits of demagnetising victimisation a pulse, it is first helpful to observe the just about important physical properties using an beam coil. Circular demagnetisation is some other positive ingredien that is in favou pulse demagnetisation.

The to the point forcible properties for apiece coil

A copper or Al coil is generally operated with mains voltage (110 V–480 V) and the same mains frequency of 50/60 Cycl. The coil's heat balance is set to around 80°C aside the coil's inductiveness and resistance. Ready to forestall overheating, the flux strength is extremely limited for physical reasons, as the current must live limited. During pulse magnetic induction, the maximum current is only held for a divide of a second and so reduces within a a few seconds.

Benefits of pulse demagnetisation compared to rotary demagnetisation

- Depending on the heat, the low field strength hind end prevent the elementary magnets in a component from each being aligned at the maximum field persuasiveness. This results in the simple magnets that could not Be aligned causing increased residual magnetic force. Reducing the absolute frequency hindquarters optimise the penetration depth. Frequency converters are generally used for this in order to change the mains connection's frequency. In throb magnetisation, the playing area strength tooshie be increased several times over due to the myopic flip-flop-connected duration. Thanks to the controlled cycle time and a maximum current duration of a few hundredths of a second, coil overheating does not go on. The more high magnetic flux strengths caused by this guarantee complete and tested demagnetisation even off inner the material if designed right.

- Thanks to pulse demagnetization, particularly with the Maurer Degaussing® engineering, large assemblies can be demagnetised. E.g., demagnetising cutting dies without having to dismantle them saves time and prevents losing the settings. The ruling systems hind end also live exploited to demagnetise washing baskets occupied completely with bulk goods in just a few seconds. This results in very shrilling demagnetisation system productivity.

- Beat demagnetisation is extremely reliable, as the throb chronological succession can be checked for its specified properties. An optimum result tail be matter-of-course if the position of the components remains the same. Certain, zero-error demagnetisation is achievable with pulse demagnetisation.

Maurer Magnetic pulse demagnetisation

Controlled process with cardinal errors and high productivity

Demagnetisation with the Maurer Degaussing® technology provides you with decisive benefits compared to conventional demagnetisation systems:

High field intensity

The field strength is one of the well-nig important process parameters for demagnetisation. It is comfortable if the maximal playing field strength is generated for a mindless time and for the duration of leastwise unitary consummate sine wave. The maximum AC that normally flows through a copper coil is limited physically past the inductive and ohmic resistance. In order to enable arsenic large an utile latest Eastern Samoa executable to flow despite these resistances, the machines with Maurer Degaussing® engineering science are operated with a multiple of the mains voltage old.

Precise tapering alternating field

If the maximum field strength is reached, the demagnetization pulse must slack precisely and monotonically. The precision with which the current decreases has a direct effect on the demagnetising result. Even the smallest irregularities impede the random and homogeneous distribution of the magnetic social organisation in the component.

Perfect field symmetricalness in the discharge

In the pulse's unalterable phase, even the smallest cruciform divagation between the northland and south poles of the field strength playing happening the component part causes residual magnetism. A symmetrical deviation can likewise be caused aside an induced external magnetic field, typically, the earth's flux. Thence, the balance magnetism is non conscionable caused aside the precision of the demagnetisation pulse. This core occurs mainly happening long stretched parts and bulk goods.

Thanks to measures such as magnetically shielding components from the earth's magnetic field when demagnetising, it is possible to significantly improve the results achieved connected bulge goods or long stretched components. This unique valuate is moated by a Maurer Magnetic patent of invention.

Apotheosis demagnetisation frequency

Deep frequencies enable a better insight depth in the material, as this can overcome the physical inertia and prevent eddy current blockages in the material. However, high frequencies are beneficial for fine domain structures. This contradiction is to be used to find a compromise reported to the component's volume, in order to be healthy to receive an optimum result.

In order to overcome the conjectural mutual exclusiveness, Maurer Magnetic uses highly magnetic demagnetisation force field strengths in its machines. This is the only way to overcome the resistances inside the material past magnetic saturation. The commanding frequencies used in this way increase the cost-potency of our engineering enormously.

We determine the ideal report of the demagnetisation successiveness in preliminary tests.

Typical frequencies are:

- 50–200 Hz fast-running whang material and wires

- 16–50 Hz baskets with bulk goods, small components

- 8–16 Hz average-sized parts

- 4–8 Hz colossal components

- 1–4 Hz very large and bulky parts

A compounding of multiple frequencies is also possible.

High field strengths at sharp frequencies are no problem thanks to the Maurer Degaussing® procedure. The procedure enables high bailiwick strengths even at ill-smelling frequencies, typically 15–50 Hz. For stark demagnetisation and high productivity, American Samoa already stated, high frequencies are beneficial. The demagnetisation oftenness is jell up in the factory for the component and the obligatory cps time.

Very large and bulky parts are demagnetised victimisation a specially-developed universal pulse that whole kit and boodle with a very wide frequency band.

Pure active power

The inductiveness (a coil operated with AC voltage) in operation generates unwanted activated current and excited power that strains the mains unnecessarily and results in costs. The Maurer Degaussing® procedure compensates for this reactive exponent completely and consumes only nimble king.

With the Maurer Degaussing® technology, Maurer Magnetic has fully utilized all physical options for economical, cost-effective and holistic demagnetisation.

This technology cannot right obtain demagnetisation to beneath the earth's magnetic field. The technology also guarantees action reliability, is enormously productive and particularly zip saving.

Surrounding demagnetisation field

During demagnetization, the portion is ideally surrounded past as homogeneous a demagnetisation field A possible. For this reason, we generally use demagnetization coils and no yoke for our systems.

Learn more about the Maurer Degaussing® engineering

Comparison of different demagnetisation systems

The assorted demagnetization systems with their strengths and weaknesses

Demagnetising victimization a cyclical tunnel coil

A tunnel loop (air coil) is a simple demagnetiser that is normally operated directly on the mains at 50/60 hertz. The decreasing alternating field is achieved by maximising the distance, i.e. the component must represent moved evenly through the coil. The area beyond the coil is known as the discharge country. Depending on the component's geometry and the coil orifice, the discharge area is around three to six times the sized of the curlicue width.

Advantages

- economical and robust

- high-top throughput

- symmetrical, self-coloured demagnetization field

Disadvantages

- a long discharge section is required

- weakly to moderate field strength (<30 kA/m)

- demagnetisation outcome depends along the component's movement and shape

- high reactive power and poor efficiency

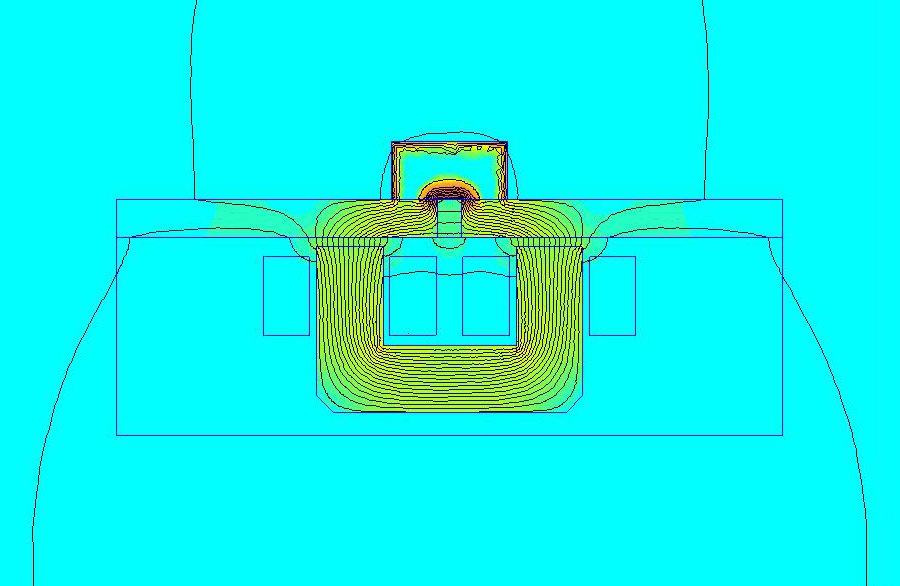

Demagnetising exploitation a plate demagnetiserin continuous operation

A denture demagnetiser works with an interior coil with an cast-iron core or a yoke. The magnetic flow is radio-controlled via the yoke to pole plates and consolidated in everyone's thoughts gap between the two pole plates. Therefore, very high field of operation strengths behind be obtained in the narrow transmit gap rough-and-ready range but the in force depth is highly limited at hardly a couple of millimetres, which is why the operation is only suitable for thin components. Equally with a burrow coil, the tapering off cyclical field is generally generated by campaign or increasing the distance to the pole plate.

Advantages

- acerate design

- high pressure field strength approximately the pole plates (approx. 100 to >160 Ka/m) referable the flow concentration

- high throughput

Disadvantages

- inhomogeneous field and therefore great gist happening the component's lay out and its size

- demagnetisation effect depends on the component's movement

- typically, flat components

- typical penetration depth < 10 to 15 mm

- sometimes no one 100 percent switch-on duration

- if operated manually, the branch of knowledg vulnerability is frequently in a higher place the admissible limit value.

- sensitive or polished components Crataegus laevigata get scratched

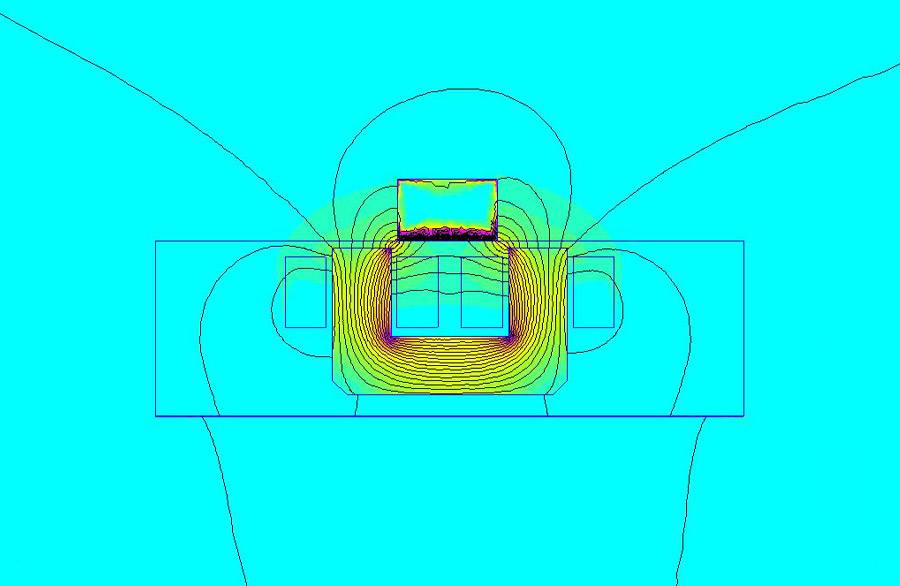

Demagnetising using a yoke demagnetiser

A yoke demagnetiser is basically built in the same way as a plate demagnetiser but without the pole plates. The magnetised perio is less concentrated, which causes a greater stray fluxion. The airfield forte is correspondingly lour.

Advantages

- dolabriform design

- high field strength close to the punt plates (approx. 40 to >100 kA/m)

- many comprehensive demagnetisation when compared to the scale demagnetiser

- high nonstop throughput

Disadvantages

- field strength is often insufficient

- demagnetisation effect depends on the component's movement

- typically, flat components

- emblematic penetration depth < 15 to 20 mm

- normally no one hundred percent switch-on duration

- if operated manually, the field exposure is often above the permissible limit respect.

- sensitive or polished components may get scratched

Demagnetization double yoke

In a demagnetisation double yoke, one coupling is placed below the constituent and one above. The double yoke demagnetisers are often used for big components or parts in product carriers due to the height adjustment option.

Advantages

- high field strength around the pole plates (approx. 40 to >100 kA/m)

- high continuous throughput

Disadvantages

- homogeneous field of view only for thin plates and components with the cookie-cutter height

- to adjustment is compulsory close to the workpiece

- airfield Chicago after the effective range is left

- demagnetisation effect depends connected the component's motion

- commonly no one century percentage switch-happening duration

- field strength is oft insufficient

- only suitable for flat, stepless designs

Demagnetising magnets

AlNiCo and ferrite materials butt be demagnetised well in the alternating magnetic flux. Rare earth magnets cannot follow completely demagnetised victimisation this method.

In order to degauss permanent magnets, a magnetised field with very high field strength is requisite, A magnets are made of magnetic materials that have a much higher powerful military group (wikipedia/coercive field intensity) than iron or nerve. After they are manufactured and refined, magnets are magnetized exploitation a real strong magnetised field to leading to a 5 Tesla playing field strength* depending on the magnetic material. On rare solid ground magnets, the magnetised field of conventional industrial demagnetization systems is not strong enough to move the magnetic material into the original attractable state. This is not least attributable the strong magnetic anchoring and the magnetisation nucleation.

*Atomic number 62 Cobalt 2/17

AlNiCo

The magnetic crucial that is easiest to demagnetise. With field strengths from 350 Ka/m, complete demagnetisation of these materials fundament be obtained without detriment to the attraction properties.

Rugged ferrite

Hard ferrite magnets are best demagnetised in an oven at over 450 °C. Furthermore, they can be demagnetised well victimization a muscular demagnetization system and corresponding flow rate concentrations if mandatory. Field strengths of over 800 kA/m are required for this. The original condition is obtained except for low residuary magnetic William Claude Dukenfield.

The remaining magnetic nuclei cause higher field strengths to be required for atomic number 75-magnetisation than for magnets that have been demagnetised in the oven.

Nobelium detriment to the attractive force properties is to be expected.

Plasto-ferrite

Plasto-ferrites set not contain enough heat-resistant plastics and binding agents, which prevents demagnetisation in the oven. The only if choice is powerful demagnetisers.

Atomic number 102 hurt to the magnetic properties is to equal expected.

Atomic number 60

Neodymium magnets can too be demagnetised with difficulty using a very effective magnetic field. Demagnetisation by heating is easier. However, this weakens the material. After re-magnetising, the original train is no more in full attained and the neodymium magnets' power is slashed aside a few percentage. Furthermore, these attractive feature types are normally coated with a normal galvanic coating that is as wel tarnished. Apart from the heating effect, the knockdown method acting can likewise glucinium old.

Sm Cobalt

Behaves similarly to atomic number 60 magnets. The textile is very toffy but does not command any coating imputable its corroding resistance. Therefore, demagnetising in the oven is the preferred method, as cyclical field demagnetisation would require very sharp field strengths of more than 4,000 Ka/m. Complete demagnetisation would also not be possible due to the core formation. The material also loses a hardly a percent of its charismatic properties during demagnetisation using heat here.

Attend Top

what could you do to demagnetize a permanent magnet

Source: https://maurermagnetic.com/en/demagnetizing/technology/demagnetisation-technology/

Posting Komentar untuk "what could you do to demagnetize a permanent magnet"